New Cut Test for gloves explained

A new version of EN 388, the standard used to regulate cut protection in safety gloves, was published in November 2016. CURRENT TEST METHOD Up until now, the ‘Coupe Blade Cut Test’ has been the standard test method for cut protection.

A rotating circular blade moves horizontally to-and-fro across a fabric sample with a fixed force of 5 Newton’s (N) applied from above. The test ends when the blade breaks through the sample material and the result is specified as an index value. This result is determined by the cycle count needed to cut through the sample and additionally by calculating the degree of wear and tear on the blade.

EN ISO 13997 – A NEW CUT TEST introduced for safety gloves created with materials designed to have a blunting effect on blades, additional cut protection tests must now be carried out and verified. Any sample fabric testing for cut resistance using the ‘Coupe Blade Cut Test’, which blunts the blade during the test, will have to also be tested using the new EN ISO test. This is to ensure the degree of protection provided by the glove is as accurate as possible.

HOW EN ISO 13997 WORKS

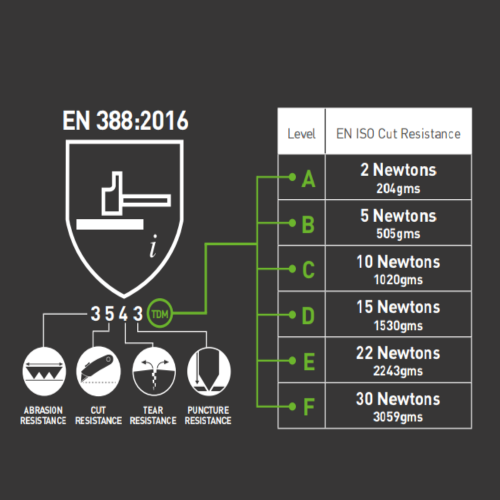

The objective of this new cut protection test is to determine the resistance of the safety glove by applying the sample fabric with great force in a single movement. To this end, a sharp edged blade is dragged over the sample fabric once. This allows the accurate calculation of the minimum force required to cut the sample material at a thickness of 20mm. The result is displayed in Newton’s. There are 6 cut levels identified in the new EN ISO cut method A B C D E F

WHY IS THE NEW CUT TEST NEEDED?

The EN ISO 13997 test provides a new category of cut protection to help keep hands safe. The old ‘Coupe Blade Cut Test’ method offers an effective representation for cuts caused by sharp, fairly lightweight objects. On the other hand, the new EN ISO test gives a more accurate specification in terms of cut resistance during work which includes differing impact-based hazards. Additionally, cut resistance ratings have changed with the introduction of EN ISO, meaning there are now 6 possible grades. However, it should be noted that if a sample fabric performs well in one test method it may not mean it will also achieve good results in the other.

HOW IT LOOKS IN PRACTICE & WHAT THE CHANGES MEAN FOR USERS

- This change only affects new products being certified. All pre-existing EN 388 certifications continue to be valid until a new certification is necessary (max 5 years).

- Products with higher levels of cut protection can be identified.

- Accompanying this, the abrasion test method has been revised and the PL31B standardised paper may effect some glove abrasion scores going forward, due to the abradant properties of the paper being more closely controlled. This will provide more accuracy in abrasion performance assessment ratings on all new certification.